Industrial Robotic Automation Solutions

Asan Teknik offers a variety of robotic automation systems designed to enhance the efficiency, speed, and reliability of your production processes. Our solutions deliver high precision and repeatability for tasks such as product stacking, packaging, palletizing, and assembly.

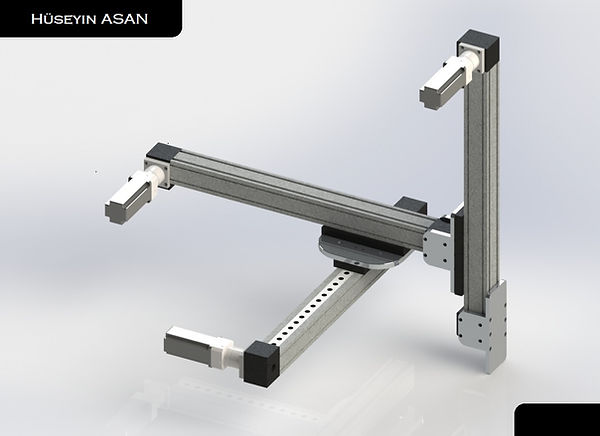

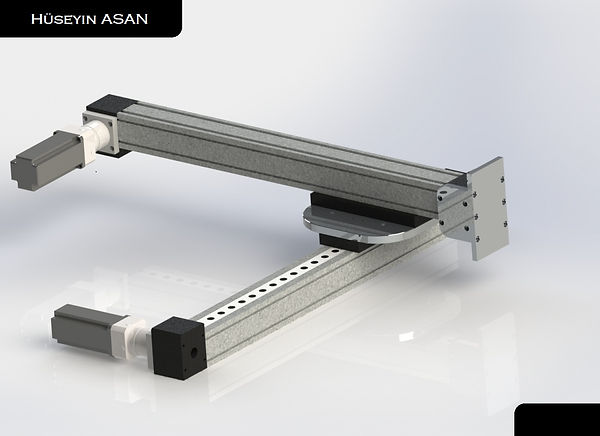

🔹 Cartesian Robot Systems

Our Cartesian robots provide movement along the X, Y, and Z axes and are especially suited for product stacking and packaging applications. Their modular design allows easy integration into different production lines.

Features:

-

High load capacity

-

Precise positioning

-

Easily programmable control system

🔹 Product Stacking and Packaging Automation

Our systems automate the arranging and packaging of products of various sizes, increasing production speed while reducing labor costs.

Advantages:

-

Compatible with standard and custom package sizes

-

Fast and repeatable operation

-

Gentle handling that preserves product integrity

🔹 5-Axis Robotic Systems

Designed for complex assembly and machining tasks, our 5-axis robots offer versatile motion capabilities and high performance even in confined spaces.

Applications:

-

Complex assembly operations

-

Precise part placement

-

Multi-angle demanding tasks

🛠️ Why Choose Asan Teknik Robotic Systems?

-

Customizable designs tailored to your production needs

-

High efficiency for fast and continuous production flow

-

Low maintenance costs with durable, long-lasting systems

-

Expert support from installation to training

📞 Contact Us

Reach out to learn more about our robotic automation solutions and find the system best suited to your needs.

Gripper / Tutucular

Multi-Grip – 4-Finger Gripper

Developed by Asan Teknik, the 4-Finger Gripper is an advanced automation solution designed to simultaneously grasp, carry, and place multiple products with precision and synchronization. It delivers maximum efficiency in production lines where small and delicate products need to be handled at high speeds without damage.

Thanks to its pneumatic or servo-controlled finger structure, it automatically adapts to products of different shapes and sizes. This feature enhances production flexibility while minimizing operator errors.

Key Features:

-

Ability to grasp and transport multiple products simultaneously

-

Precise and balanced grip with 4-finger design

-

Pneumatic or servo-controlled gripping mechanism

-

Automatic grip adjustment according to product size

-

Fast cycle time and high repeatability

Typical Applications:

-

Electronic component placement lines

-

Collection of delicate product groups in the food industry

-

Multi-grip applications in automatic assembly and feeding systems

-

Product sorting and transportation operations before packaging

Needle Gripper – Food Grade

The Needle Gripper is a specialized gripping system designed for the delicate and secure handling of irregularly shaped or vacuum-ungrippable food products before packaging. Developed by Asan Teknik, this system integrates seamlessly into production lines with its food-grade stainless steel construction and hygienic design.

The needles penetrate the product surface with minimal contact, preventing deformation and crushing. This makes it ideal for handling sensitive products such as wafers, cakes, and soft snacks. Its compact structure allows easy use in fast-paced, confined production areas.

Key Features:

-

Food industry compatible stainless steel and hygienic design

-

Grip without deforming products using fine needle tips

-

Pneumatic or servo-controlled precise movement system

-

Easily detachable for quick cleaning and maintenance

-

Durable mechanism suitable for high-speed repetitive operations

Typical Applications:

-

Product orientation on wafer, biscuit, and cake lines

-

Feeding products into delicate packaging machines

-

Transfer of irregular or vacuum-ungrippable food items

-

Use in automatic tray stacking or line transfer points

Sliding Gripper – High Precision Mechanical Grip

The Sliding Gripper is a versatile handling solution with movable mechanical fingers that can securely, precisely, and evenly grip products of varying sizes. Designed for integration into industrial automation systems, it offers flexibility especially in production lines where differently sized parts need to be directed through a single conveyor.

Developed by Asan Teknik, this system features an adjustable opening distance via a linear sliding mechanism, enabling stable and seamless performance in both precise assembly applications and high-repeat transport operations.

Key Features:

-

Adjustable opening distance to accommodate different product sizes

-

Mechanical precision through a linear sliding system

-

Available in pneumatic or servo-controlled versions

-

Durable aluminum and steel construction

-

Compact design for easy integration into tight spaces

Typical Applications:

-

Part handling in automotive and white goods production lines

-

Precise gripping in electronic assembly and testing systems

-

Post-plastic injection part picking

-

Multi-product selection and sorting automation

Bottle Holding / Handling Gripper – Fast and Secure Bottle Gripping System

The Bottle Holding Gripper is a high-performance gripping system specifically developed for in-line handling, sorting, and directing of plastic or glass bottles. It ensures precise and balanced gripping on the neck, body, or base of bottles, providing maximum efficiency throughout the production process.

Designed by Asan Teknik, this gripper can operate with pneumatic or servo control, easily adapting to different bottle diameters. Thanks to specially coated gripping surfaces that reduce deformation risks, it is especially suitable for use in the food, beverage, and cosmetics industries with high hygiene standards.

Key Features:

-

Automatic adaptation to different bottle sizes

-

Soft gripping surfaces for deformation-free handling

-

Fast gripping and releasing cycles for high throughput

-

Pneumatic or servo motor control options

-

Stainless steel and hygienic material selection suitable for food contact

Typical Applications:

-

Beverage filling and labeling lines

-

Food packaging systems

-

Cosmetic product handling and sorting robots

-

Post-plastic blow molding line integration

-

Glass bottle handling and directing applications

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces

Needle Open/Close Gripper Automation – Precise and Reliable Product Handling Solution

The needle gripper system is a high-precision automation solution designed especially for safely gripping and handling delicate, flat-surfaced food products such as wafers, chocolates, and biscuits. Thanks to the fine needle tips that grip without damaging the product’s top surface, product deformation is minimized.

The open-close function is controlled by regulated air pressure or a servo mechanism. Products do not slip or misalign during transport and the system can synchronize seamlessly with robotic automation.

Key Features:

-

Delicate needle gripping that does not damage product surfaces

-

Stainless, hygienic design suitable for food contact

-

Controlled open/close mechanism for enhanced safety

-

Fast cycle times with high repeatability

-

Optimized for delicate products like wafers and chocolates

Typical Applications:

-

Picking and placing products on wafer production lines

-

Pre-packaging sorting in chocolate and confectionery production

-

Delicate transport systems in the food industry

-

Automated arranging and alignment processes

-

Handling smooth, flat, and hole-free product surfaces